新闻中心

Related sections:Titanium dioxide in the paper industry

- Font size + -

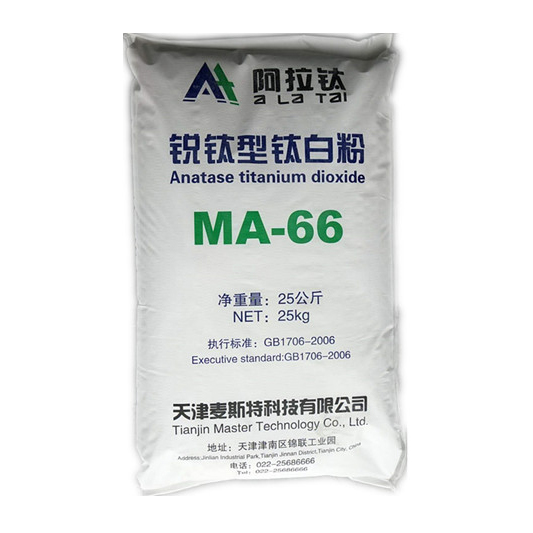

Papermaking is the third largest user of titanium dioxide. Titanium dioxide is generally used in decorative paper, bible paper, and banknotes. Titanium dioxide paper is used. The paper has good whiteness, high strength, gloss, thinness and smoothness, and does not penetrate during printing. Under the same conditions, the opacity is lower than that of calcium carbonate. 10 times higher talcum powder, quality can also reduce 15% to 30%. Decorative paper, also known as titanium white paper, is mainly used to make raw materials for furniture, flooring, wallpaper, etc. For papers with anti-aging requirements, rutile must be used; more rutile is used in high-ash paper. Rutile must be used for this high-ash paper because the hiding power of anatase titanium dioxide cannot reach. Claim.

Anatase titanium dioxide is used in low ash paper, such as bible paper and banknotes. The Bible paper requires good opacity of the paper. Generally, it can be satisfied by using anatase titanium dioxide; the coinage paper also requires very For good opacity, anatase is also used. In China, titanium dioxide used in decorative paper is much higher than the other two varieties. This situation is determined by the level of consumption in our country. According to incomplete estimates, titanium dioxide used for decorative paper in China exceeds 30,000 tons per year.

Decorative paper titanium dioxide dosage 20% to 40%, other paper titanium white 1% to 5%. Rutile is used for weather-resistant, high-ash paper, and Anatase is used for papers with low weatherability and low ash. The main reason for determining what kind of titanium dioxide is used by paper mills is the cost of papermaking, that is, the cost-effectiveness of titanium dioxide. . As the proportion of titanium dioxide in papermaking costs as high as 30% to 50%, the paper mills can be said to be preoccupied with the choice of titanium dioxide when they meet the requirements of users. Never use rutile for the use of anatase. The paper industry's requirements for the quality of titanium white are in order of importance:

First, hiding power (opacity): Paper containing the same titanium dioxide can cover the background color ability, this index determines the cost of titanium dioxide. Simply put, titanium dioxide with high hiding power is generally high in price, but it is used in small quantities, so the cost of titanium dioxide per ton of paper may be lower; titanium dioxide with low hiding power, although with low price, but with large amount, leads to one ton The cost of titanium dioxide in paper increases;

Second, whiteness: The whiteness of titanium white determines the appearance of the paper after molding;

Third, the dispersion: the current papermaking process generally use dispersants, therefore, the water dispersibility of titanium white is not much difference;

Fourth, weather resistance: Domestic rutile can meet the weatherability requirements of most paper, only a few papers require rutile to provide high weather resistance;

V. Retention rate: The paper industry recycles filtered water or uses retention aids. Generally, the recovery rate of titanium dioxide is above 99%. The reason why this index is retained is because the international large titanium white company is promoting sales. Titanium dioxide for paper-making uses both retention aid formulations and methods of use to improve service quality and increase product competitiveness.

related news

- 2024-04-08

MECS 16-18 APRIL 2024

- 2023-12-28

Notification letter to customers

- 2023-12-25

Merry Christmas and Happy New Year

- 2023-12-19

CHINACOAT2023 IN SHANGHAI(NOV.14TH-17

- 2018-04-11

Talking about the Quality Requirements…

- 2018-04-11

New Technology of Calcined Rotary Kiln…

- 2018-04-11

How to distinguish the authenticity of…

- 2018-04-11

Introduction of titanium dioxide in fu…

- 2018-04-11

What are the important factors that af…

- 2018-04-11

Titanium dioxide in the paper indust