新闻中心

Related sections:Talking about the Quality Requirements of Ink on Titanium Dioxide Pigment

- Font size + -

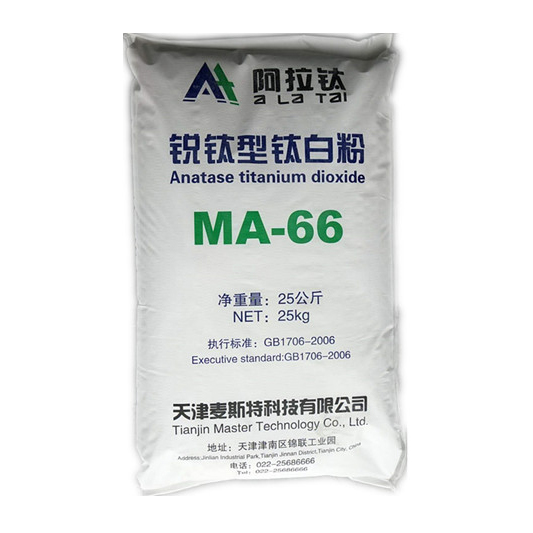

In the ink production process, the quality requirements of different types of ink products on titanium pigments are also different. Titanium dioxide (titanium dioxide) product types are classified into rutile and anatase titanium dioxide. Practice has proved that anatase titanium dioxide has the ideal application performance and can be widely used in the preparation of various types of inks. Many customers have reported that compared with other titanium pigments, anatase titanium dioxide pigments have many advantages and are widely used in ink production. What are the quality requirements for titanium dioxide pigments? First of all, let's first look at some of the characteristics of the use of various ink it!

1. The use of various ink features:

(1) Offset printing ink:

Offset ink has two major properties: anti-emulsification, hydrophobicity. Note that the white offset inks used for long-term storage in outdoor printing products require good lightfastness and weatherability in titanium dioxide pigments to be formulated, otherwise yellowing or powdering may occur.

(2) Gravure composite film ink:

In order to make the printed products colorful, beautiful appearance, many manufacturers use white ink to make a base, and then carry out color printing. Therefore, the requirements for titanium dioxide pigments are good coloring power and hiding power.

(3) baking type printing white ink:

The product should be well-controlled after baking, and it is recommended to cook at about 180°C for 2 hours. Therefore, the requirements of titanium dioxide on titanium white ink is to have good heat resistance.

2. The use of integrated ink characteristics, the quality requirements of the titanium dioxide pigment mainly has the following points:

(1) Good hiding power and strong coloring power.

(2) It has strong weatherability, heat resistance, and chemical stability.

(3) The whiteness is good, the durability is not yellowed, and the printed product can be kept bright in any environment.

(4) The powder particles are small, and the ink is dispersed more uniformly during use.

related news

- 2024-04-08

MECS 16-18 APRIL 2024

- 2023-12-28

Notification letter to customers

- 2023-12-25

Merry Christmas and Happy New Year

- 2023-12-19

CHINACOAT2023 IN SHANGHAI(NOV.14TH-17

- 2018-04-11

Talking about the Quality Requirements…

- 2018-04-11

New Technology of Calcined Rotary Kiln…

- 2018-04-11

How to distinguish the authenticity of…

- 2018-04-11

Introduction of titanium dioxide in fu…

- 2018-04-11

What are the important factors that af…

- 2018-04-11

Titanium dioxide in the paper indust